Manufacturing the Future

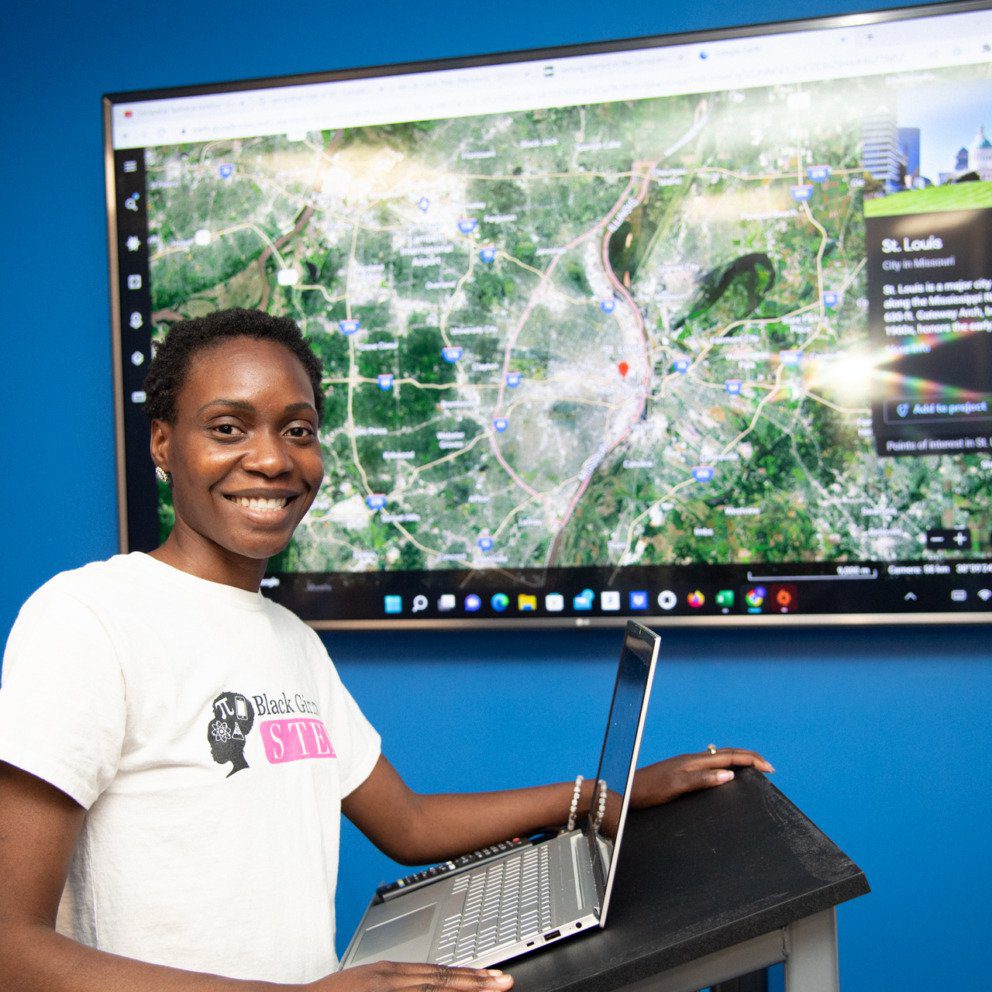

Southwestern Illinois College leads the way in educating the next generation of manufacturing workers, helping to realize the vision of a thriving advanced manufacturing industry that will drive inclusive economic growth in St. Louis.

In 2022, educator Mark Bosworth visited 52 elementary, middle and high schools across the Metro East to promote the advanced manufacturing trade using his grant-funded “mobile CNC lab”— a 42-foot Featherlite trailer equipped with six high-tech machines that operate via computer numerical control (CNC).

Bosworth, who serves as industrial technology coordinator at Southwestern Illinois College in addition to working as a weekend machinist at Anheuser-Busch, describes CNC machines as the “lifeblood” of the field. The increased reliance on computation and automation, the use of cutting-edge materials and processes and a more skilled labor pool is what differentiates advanced manufacturing, according to the President’s Council of Advisors on Science and Technology.

The demand for this skilled labor has become a crisis of sorts in Missouri and beyond — nationwide, the industry is expected to have 2.1 million unfilled jobs by 2030, according to a joint report issued by Deloitte and The Manufacturing Institute — but Bosworth is optimistic about SWIC’s recruitment efforts. “I’ve been in education now over 25 years, and I’ve always been a firm believer that if you have a good pipeline of students, including high school and college programs, companies will see that and build their companies in this area,” he says.

An entire advanced manufacturing ecosystem is now burgeoning throughout the St. Louis region to support the development of this pipeline. Civic and business leaders are investing in the construction of an Advanced Manufacturing Innovation Center, to be located in North St. Louis near Ranken Technical College. The center will facilitate leading-edge research and development activities as well as talent development and is designed to bridge different high-tech industries, including aerospace, automotive, biomedical and more. And on the educational side, a network of institutions are expanding their advanced manufacturing programs, including St. Louis Community College Florissant Valley; Heartland Community College in Normal, Illinois; and SWIC.

Even prior to its moves toward expansion, though, SWIC has held a central position inside this ecosystem, Bosworth says. “If you look at the Arch as the center, SWIC is the central hub of the manufacturing sector in this region,” he explains. “We have companies from Mount Vernon, Illinois, all the way out to Washington, Missouri, up north to Hannibal and down south by Cape Girardeau calling for our students when they need employees.”

Plans for further growth include renovations to SWIC’s Granite City campus, where it will consolidate and centralize its supply of CNC machines. The college also is building a new training academy in Belleville, Illinois, which will be home to three new certificates in advanced manufacturing. These include machine automation, for which students will learn a higher level of CNC coding as well as how to program robots; additive manufacturing, where they’ll work with 3D printers to print stainless steel, titanium and other exotic metals; and tool and die mold making, which involves stamping dies to create sheet metal parts for a wide range of industries, from automotive to home appliances.

Partial funding for these initiatives comes from the highly competitive federal Build Back Better Regional Challenge grant, submitted by Greater St. Louis Inc. and awarded in September 2022 to a coalition of local organizations including SWIC, AMICSTL and Rung for Women, a local nonprofit dedicated to helping women climb the economic opportunity ladder.

The grant supports a vision for St. Louis’ economic future that posits advanced manufacturing on par with agtech and geospatial as part of a three-pronged strategy for innovation and growth. Going a step further, it suggests the trade can play a meaningful role in St. Louis’ vision for economic justice. Toward this end, $1 million in funds have been allocated to Rung for Women to help recruit more women and people of color to the field.

SWIC’s current students make a compelling case for joining the industry. Aiden Johnson, Lemola Mason and Cody Croxford are enrolled in the college’s precision machining technology PMT pathway, a two-year associate’s degree program established in 2008. They each have a unique perspective on the benefits of pursuing a manufacturing career.

Johnson, who grew up roughly 50 minutes east of St. Louis in Greenville, Illinois, emphasizes the accessibility of the curriculum. “If someone’s looking into the machining world, it might seem really overwhelming, but it’s really not,” he says. “We’re programming $150,000 machines, and you might think it would be super complicated, but after the first week we were able to write basic programs. It’s just a coordinate system, and you tell the machine where to move. It’s super simple, and a lot of fun, too.”

Mason, a native of Hazelwood, points out the abundance of manufacturing jobs as well as the tangible outcomes of a day’s work. “You really feel like you’ve accomplished something every day,” he says. “You start off with a solid piece of steel, and after a couple of hours when it’s time for you to leave, you’ve turned it into this small, intricate part.”

Croxford, who comes from a small town 45 minutes north of St. Louis, echoes this sentiment: “You take so much pride in what your finished parts look like, coming from nothing to something that’s super useful.”

Part-time apprenticeship arrangements that provide funding and real-world experience are widely available to these students, Bosworth says. Mason, who transferred to SWIC after starting a degree in computer science at Tennessee State University, works part-time at Seyer Industries, and the company recently offered to pay his full tuition. “I always tell students when I recruit them, there are a lot of companies out there that will work around your school schedule and pay you part-time wages,” Bosworth explains. “There are a lot of little shops around the 50-employee range, and they all need workers.”

Additional scholarship opportunities abound. Croxford receives funding from the Gene Haas Foundation, which distributes a total of $20,000 to $30,000 annually to various SWIC students in the amount of several thousand dollars each, Bosworth says. Students need only complete a single, central application to apply for an array of scholarships, he adds, also noting the relative affordability of SWIC tuition, which amounts to roughly $14,000 for the two-year associate’s degree.

Another source of student funding is national machining competitions, such as the SkillsUSA and Project MFG contests. The latter is a newer competition sponsored by the Department of Defense. Last year, a team of three SWIC students won first place in the nation at the event, each personally earning $17,000 in addition to $50,000 toward SWIC’s program. The students traveled to South Carolina this May to defend their national championship.

However, manufacturing work holds plenty of intrinsic rewards beyond monetary compensation, the students say. The fun of operating cutting-edge equipment is a motivator for Mason. “CNC machines are pretty awesome,” he says. “It’s amazing to see how much power and accuracy they have.”

Bosworth, who has worked in the field for nearly three decades, relishes the chance to see his impact on the products of store shelves. Even in an industry centered on the values of precision, details and accuracy, there’s a chance to have a more sweeping impact, he says. “When I was in the stamping and die industry, I would go to Sears and Roebuck, and I’d see a stove there, and I’d think, I had a part in making that stove there, and it’s going to be in thousands and thousands of houses,” he recalls.

“It’s the pride our students take in being part of something bigger, and it’s a very rewarding career for that.”

Join the Story

- Learn more about SWIC’s academic programs.

- Read the St. Louis Public Radio story on how St. Louis’ economic future requires a lot more trained workers, and fast.

- Check out our story on another initiative focused on inclusive economic growth: Trading Up.